How Wireless Backup Cameras Cut Downtime & Maintenance Costs

Vehicle management faces constant challenges, with downtime and maintenance expenses often taking a toll on profitability. Every minute a vehicle spends off-road translates into lost revenue and increased operational costs. Wireless backup camera systems provide a practical solution by minimizing downtime, preventing costly repairs, and streamlining maintenance processes. This article explores exactly how these innovative systems slash downtime and maintenance expenses, supported by real-world examples, detailed analysis, and actionable insights.

1. What Are Wireless Backup Camera Systems?

Wireless backup camera systems utilize rear-mounted cameras transmitting real-time footage to an in-cabin display. They eliminate blind spots, improving safety during reversing maneuvers. But here’s the kicker… these systems use wireless connectivity, reducing complicated installations typical with wired solutions.

These systems include a weather-resistant camera, wireless transmitter, receiver, and display monitor. Advanced models integrate GPS, infrared capabilities, and robust encryption to ensure security and reliability.

Unlike traditional wired systems requiring extensive labor and downtime during installation, wireless cameras install rapidly—often within an hour. Wired installations can take several hours, impacting productivity.

| Features | Wireless Systems | Wired Systems |

|---|---|---|

| Installation time | 1 hour | 4-6 hours |

| Maintenance complexity | Minimal | Moderate-high |

| Scalability | Easy | Difficult |

| Cost-effectiveness | High | Medium |

2. Why Does Downtime Matter?

Downtime refers to periods vehicles are unavailable due to repairs or maintenance. Unplanned downtime directly impacts productivity and service delivery timelines.

A logistics company reported losing approximately $2,000 per vehicle per day in downtime-related costs, encompassing delayed deliveries, emergency repairs, and idle workforce.

Minimizing downtime directly enhances availability and operational efficiency. Wireless backup camera systems provide proactive fault detection and reduce accident rates, substantially cutting downtime.

3. How Do Backup Cameras Prevent Vehicle Damage?

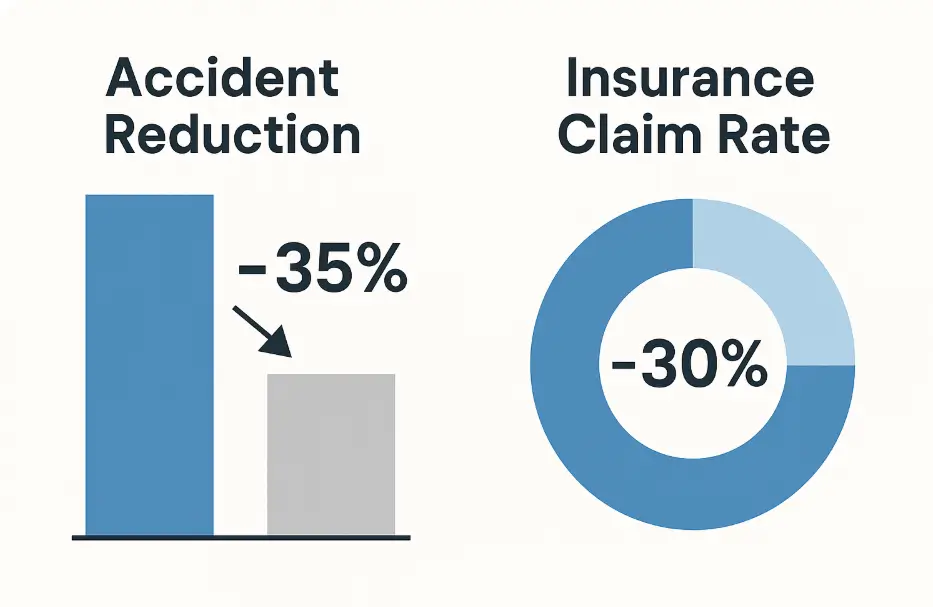

Reversing collisions represent one of the most frequent accident types, costing thousands annually. Blind spots increase collision risks significantly.

Wireless backup cameras deliver real-time visual feeds to drivers, eliminating blind spots and significantly reducing accident likelihood.

After implementing wireless backup camera systems, a municipal vehicle operation reduced reversing-related incidents by 60%, translating to annual savings exceeding $150,000.

| Incident Type | Annual Occurrences Before Cameras | After Installation | Cost Savings |

| Minor collisions | 30 | 10 | $50,000 |

| Major collisions | 5 | 1 | $100,000 |

4. How Do Wireless Backup Camera Systems Identify Maintenance Issues Early?

High-quality video feeds allow early identification of potential mechanical issues, such as loose components or damaged tires.

Advanced wireless systems alert maintenance teams proactively.

A trucking company leveraged camera visuals to detect tire tread wear early, reducing tire-related breakdowns by 40%.

5. Can Wireless Backup Cameras Reduce Labor Costs?

Wireless cameras reduce the necessity for frequent manual vehicle checks, freeing maintenance personnel for higher-value tasks.

Early fault detection significantly reduces emergency repairs and associated labor overtime.

One operator reported a 30% reduction in labor costs related to unscheduled inspections and urgent repairs within one year of installation.

| Activity Type | Hours Saved per Month | Annual Labor Savings |

| Manual inspections | 60 | $36,000 |

| Emergency repair labor | 40 | $24,000 |

6. How Do Wireless Backup Cameras Minimize Vehicle Downtime Specifically?

Real-time alerts enable prompt attention to mechanical issues, significantly reducing downtime duration.

Wireless systems help maintenance teams plan proactive repairs, minimizing vehicle immobilization.

One distribution company reported a 45% reduction in downtime after deploying wireless backup cameras.

7. What Cost Savings Can Be Expected from Reduced Downtime?

Costs include lost productivity, emergency repairs, vehicle rentals, and overtime payments.

A nationwide logistics firm reduced downtime-related costs by $300,000 annually post-installation.

Long-term savings can easily reach millions, especially in larger operations.

| Cost Category | Before Cameras | After Cameras | Annual Savings |

| Emergency repairs | $200,000 | $50,000 | $150,000 |

| Lost productivity | $500,000 | $250,000 | $250,000 |

Conclusion

Wireless backup camera systems drastically reduce downtime and maintenance expenses through proactive detection, reduced accident rates, and streamlined maintenance processes. Adopting these systems translates into significant operational savings and increased efficiency. Investing in wireless backup camera technology positions your operation to maximize productivity, profitability, and safety.

FAQ

Q1: What is a wireless backup camera system? A wireless backup camera system transmits real-time video from rear-mounted cameras to an in-cab display, assisting drivers in safe reversing.

Q2: How does a wireless backup camera system work? It captures and transmits video wirelessly, eliminating blind spots and providing real-time visual data directly to the driver’s monitor.

Q3: Do wireless backup camera systems really save money? Absolutely. They significantly reduce accidents, downtime, labor, and maintenance costs, resulting in considerable long-term savings.

Q4: How long does it take to see ROI from installing wireless backup camera systems? Most operations realize measurable returns within 6–12 months due to fewer accidents, less downtime, and reduced maintenance expenses.