Problem: Accident costs rise. Audits add pressure. Evidence is thin.

Solution: A forklift camera system that gives drivers clear views and managers clean clips.

Credibility: Yuwei builds and supplies vehicle safety systems to DCs, ports, and plants worldwide.

Heads-up: Short and direct. Use this page as a sales asset.

Who Buys and Why

Key point: Each role signs off for a different reason.

- HSE / Operations: fewer incidents, clear reports, fast training.

- Fleet manager: uptime, easy swap, simple spares.

- IT / OT: RTSP/ONVIF, VLAN plan, open API.

- Finance: 12–18-month payback.

- Procurement: reliable lead time, stable BOM, firm SLA.

Try this: Map one proof point per role in every quote.

Market Snapshot

So what now? Budgets link to audits, insurance, and evidence.

- Triggers: near-miss without proof, new site launch, premium jump, OSHA/WorkSafe visit.

- Timing: DCs buy before peak season; plants align with capex windows; ports buy in batches.

- Retrofit vs OEM: retrofit moves fast; OEM builds standardize at scale.

- Regions: US/EU drive compliance; ANZ acts fast; LATAM/ME grow via distributors.

Product Patterns That Win

Keep it rugged. Real masts expose weak kits.

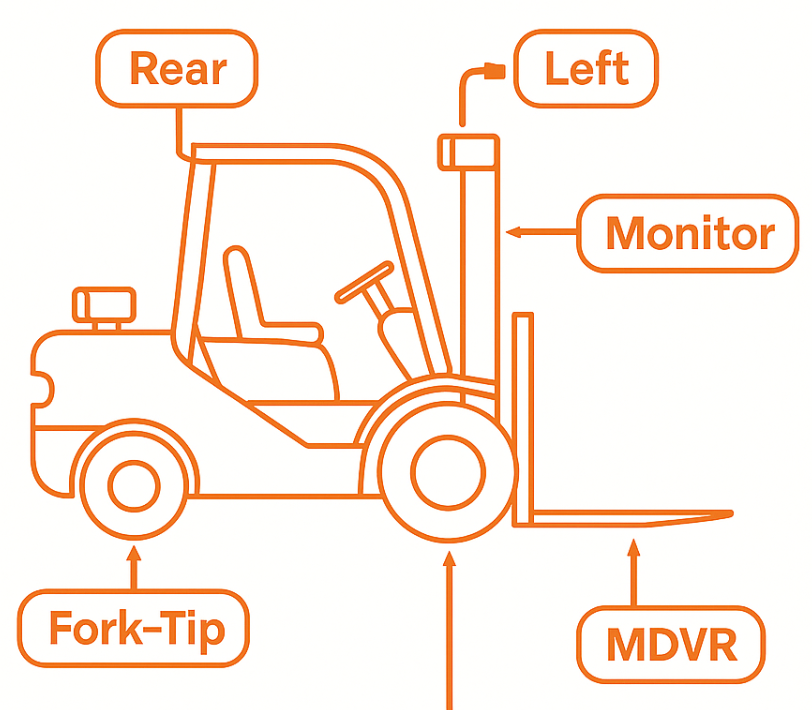

- Cameras: rear, fork-tip, and sides. IP69K. Strong low-light.

- Monitors: 7–10.1″, quad view, trigger by reverse/tilt.

- Recording: 4–8 CH MDVR with SSD, GPS, Wi-Fi.

- AI add-ons: people detect, zone alerts, speed gating.

- Power: 12/24/36/48 V readiness. Good EMI behavior.

- Mounts & looms: guards, shrouds, armoured cables, labeled routes.

Result: Drivers see more. Managers pull clips. Auditors get proof.

Forklift Camera System for Warehouses

Why this matters: Aisles are tight. Pallets stack high. People move fast.

- Rear view helps reversing in narrow lanes.

- Side views cover blind corners and cross-traffic.

- A fork tip camera for high-rack picking supports precise placement at height.

- Monitors switch by triggers, so drivers keep focus during moves.

- Event clips capture near-miss data for tool-box talks.

Tip: Add guards on busy docks to reduce camera damage.

Forklift Rear View Camera for DCs

Real gain: DCs handle speed, shifts, and seasonal peaks.

- Wide lens on counterweight improves reversing near docks.

- WDR handles sun-to-shade moves at dock doors.

- Buzzer output warns during zone breaches near pedestrians.

- Pair with a 9–10.1″ monitor for clear quad layouts.

Hint: Set a glare test at noon on the dock before sign-off.

Fork Tip Camera for High-Rack Picking

What changes: Height hides forks. Tele lens fixes that.

- Telephoto lens (e.g., 8–12 mm) shows fork tips on top tiers.

- Heated shroud keeps the lens clear in cold rooms.

- Mount on the inner mast with sleeved looms to avoid pinch points.

- Add a small grid overlay to help alignment.

Outcome: Faster placement. Fewer rack bumps. Better QA photos.

Forklift MDVR Recording Policy

Keep it simple: Record what matters. Respect privacy.

- Continuous loop: 3–7 days on SSD for internal review.

- Event clips: 15–30 seconds around triggers or AI alerts.

- Retention: hold events 90–180 days, based on policy.

- Privacy: face masks on device, watermark, timestamp, tamper flag.

- Access: role-based download, audit trail for exports.

Why this helps: You get clean evidence without heavy storage.

Tech Trends (2025–2027)

What’s next: Edge first. Cloud light.

- On-edge analytics cut delay and data cost.

- Dual-monitor setups: driver view plus supervisor coaching.

- Policy recording with short retention and on-device masks.

- APIs move JSON events into WMS/telematics/BI. RTSP moves streams to VMS.

- Battery trucks demand low draw and tight EMI control.

- IP69K and 5–8G shock are standard expectations now.

Compliance and Evidence

Make proof easy. Auditors will ask.

- Standards often cited: OSHA 1910.178, ANSI B56.1, ISO 3691-1/-5.

- Evidence pack: timestamp, watermark, tamper-evident export.

- Data rules: GDPR/CCPA push short retention and masking.

Action: Ship a one-page “evidence spec” with every quote.

Integration That Reduces Friction

Less pushback. Faster sign-off.

- On-prem first: SSD recording, Wi-Fi offload at docks.

- Selective cloud: upload events and requests only.

- Simple streams: RTSP/ONVIF into current VMS.

- JSON/REST events into WMS or safety dashboards.

Pricing and ROI That Lands

CFOs buy math. Keep it clear.

- Bundle: hardware + brackets + install + training + SLA.

- Rollout: start on 20–30% of fleet; expand after 60–90 days.

- Payback: fewer contacts, lower damage, faster claims, premium relief.

- Pilot: 20 trucks, with a clip review report in week two.

6-Week Rollout (20 Trucks)

Here’s the plan: Repeatable and calm.

- Week 0: scope fleet, voltages, mast types, recording policy, network plan.

- Week 1: install 4 trucks, toolbox talk, baseline metrics.

- Week 2: tune zones and triggers, lock SOP v1.0.

- Week 3–4: add 16 trucks, daily QA photos, manager clip reviews.

- Week 5: audit 20 event clips; driver and supervisor survey.

- Week 6: KPI pack; approve phase-2 order.

Targets: false alerts < 5%. Uptime > 99%.

Risks and Safeguards

Control the variables. Sites get noisy.

- Wireless drop on tough runs → switch those lines to wired AHD.

- False alerts in busy aisles → add speed gating and dwell timers.

- Camera hits from pallets → fit guards and keep spare kits.

- Change fatigue → short toolbox talks and driver champions.

What Buyers Expect From a Supplier

Trust wins. Bring proof, not hype.

- Bracket list with model photos.

- EMI plan for 36/48 V trucks.

- One-page network diagram and API notes.

- Install SOP, calibration sheet, QA sign-off form.

- RMA rules with advance replacement for DOA.

Recommended Kit Lineup

Three tiers. One story. Match risk and budget.

AI: multi-cam + AI MDVR for people/zone alerts and root cause

Basic: rear + monitor for reversing and aisles.

Pro: rear + sides + MDVR for incident review.

FAQ

How fast do sites reach payback?

Most see 6–18 months, driven by lower damage and fewer recordables.

Wired or wireless on forklifts?

Both work. Use wired AHD on high-EMI lines. Use digital wireless on rentals or complex runs.

Can this connect with WMS or telematics?

Yes. Send JSON events and offer RTSP streams. Start with alerts, then add clip requests.

How much training do drivers need?

A 15-minute talk and a one-page monitor guide. Run a 30-day clip review.

What spec should be non-negotiable?

IP69K cameras, anti-shock MDVR, clear night view, stable EMI behavior, and a firm SLA