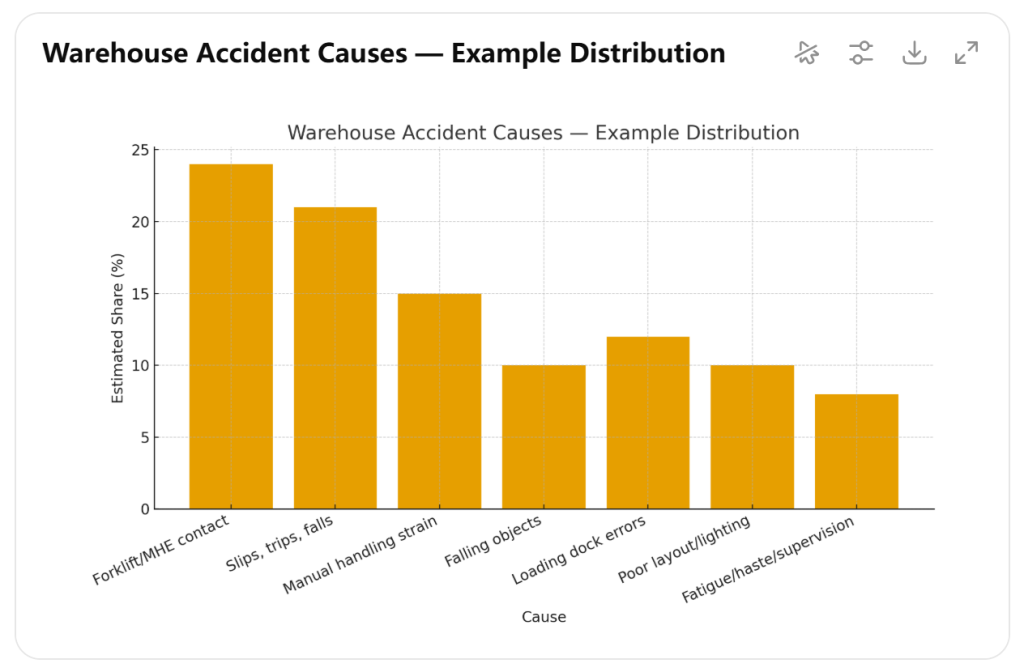

Warehouse accidents hit people and margins, so leaders need fast controls that crews can use today. Your team faces mixed traffic, tight aisles, and time pressure, which means small misses turn big without warning. Here’s the deal. This guide maps common warehouse accident causes and gives simple steps that prevent warehouse accidents during peak shifts. You’ll get practical warehouse safety tips for forklifts, docks, floors, and racks, plus quick checklists any supervisor can run before the start of a shift. Use these moves, track a few KPIs, then share short wins during daily huddles. Safer flow follows steady habits, not posters.

1. What counts as a warehouse accident?

Here’s the deal.

● Record types and fields needed for trend work

● Boundary examples that cause confusion

● Typical event types by zone: docks, aisles, racks, yards

● Inclusion rules for contractor and visitor incidents

● Simple rules that keep data clean

● Examples that sit on the boundary and how to classify them

● Policy wording that supervisors can teach in five minutes

● Data fields that matter for trend analysis, including common warehouse accident causes for each zone

2. Why do warehouse accidents spike during peak hours?

What’s the real story?

● Staffing, fatigue, and schedule pressure

● Slips, trips, and falls on wet or uneven floors

● Manual handling strain during picks, rework, or wrap

● Falling objects from racks or unstable pallets

● Loading dock errors including early pull-away

● Poor layout, blind corners, weak lighting, mixed flows

● Traffic density around pick faces

● Short huddles that prevent warehouse accidents

3. How do forklifts and MHE raise risk during busy shifts?

But here’s the kicker.

● Blind spots from loads and mast profiles

● Tail swing and turning radius in tight aisles

● Speed creep under schedule pressure

● Hand signals, spotter roles, and radio callouts

● Pre-use checks: brakes, lights, horn, chains, tires

● Cameras on forks, mast, and rear arc for context

● Proximity tags and alert zones for mixed traffic

● Practical warehouse safety tips for drivers and walkers that prevent warehouse accidents during peaks

4. Where do slips, trips, and falls cluster, and why?

Ready for the good part?

● Docks, wash zones, battery rooms, freezer thresholds

● Floor joints, loose wrap tails, debris patterns

● Cable routing during maintenance days

● Footwear grip matched to floor type

● Lighting near stairs, bends, and intersections

● Spill kits, matting strategy, and quick clean routines

● Housekeeping standards that cut repeat events fast

● Warehouse accident prevention tips for floor care, lighting checks, and footwear policy

5. Which layout changes cut warehouse accidents fastest?

Heads up.

● Early pull-away and trailer creep risks

● Leveler lip faults and gap hazards

● Chocks vs vehicle restraints and where each fits

● Light tree logic drivers understand at a glance

● Mirror placement for approach alignment

● Five-minute dock checks at shift start

● Evidence capture for coaching and claims

● Focused warehouse safety tips for docks that prevent warehouse accidents during live loading

6. What storage and racking issues drive harm?

Here’s the pivot.

● Beam overload, damage, and loose anchors

● Pallet quality, wrap tension, and unit load stability

● Putaway errors that stack risk into hot zones

● Tagging and repair workflows that stay visible

● Load signage and aisle labels that cut guesswork

● Photo standards for defect reporting\

● Height limits for hand stacking and picks

● Warehouse accident prevention tips that target racking inspection cadence and pallet quality

7. How does site layout shape traffic safety?

Let’s make this simple.

● One-way routes, crossing points, aisle priority rules

● Pedestrian lanes, guardrails, and swing gates

● Mirrors at endcaps and tight bends

● Signage height, font, contrast, and placement

● Pull staging away from corners by one bay

● LEDs that brighten gray corners and rack ends

● Mapping current flows and choosing pilot corners

● Layout-focused warehouse safety tips that reduce collision risk and prevent warehouse accidents

8. Which training formats actually stick for busy crews?

Now, the punchline.

● Day-one onboarding with live walk-throughs

● Micro-learning clips from your own cameras

● Toolbox talks with one topic and one demo

● Peer coaching during walk rounds

● QR quizzes near time clocks

● Cadence tied to role risk and season

● Behavior checks that confirm retention

● Training-centered warehouse accident prevention tips for supervisors and line leads

9. What PPE and ergonomics matter most right now?

Here’s what changes outcomes.

● Hi-vis, helmets, eyewear, and glove choices by task

● Footwear grip and replacement cycles

● Lift aids, height-adjust benches, and turntables

● Task rotation for high-strain roles

● Hearing protection fit checks in noisy bays

● Storage and cleaning routines that keep gear ready

● Procurement specs tied to incident data

● Practical warehouse safety tips for PPE fit, care, and replacement timing

10. What tech helps prevent warehouse accidents today?

This is where it gets practical.

● Forklift cameras with split-screen views

● Proximity sensors and pedestrian tags in mixed zones

● MDVR for multi-channel evidence and coaching

● Dock cameras linked with light trees and restraints

● Simple dashboards that show alerts by zone and hour

● Alert tuning that avoids noise fatigue

● IP-rated housings and shock-proof mounts

● Data-led warehouse accident prevention tips that target blind spots and high-risk time windows

11. How do inspections and checklists stop repeats?

Here’s the move that sticks.

● One page per zone: docks, aisles, racks, yards

● Photo pairs that show correct vs incorrect

● Five-minute supervisor walks at shift start

● Two-minute mid-shift checks by line leads

● Weekly manager tours with rotating focus

● Owner, due time, and close-out board that stays public

● Camera clips to verify fixes where relevant

● Short, visual checklists translate into warehouse accident prevention tips crews can follow

12. What should incident response include from minute one?

Pay attention to this.

● First aid and scene control steps

● Photos, video, time stamps, and witness notes

● Isolate gear and area until reviewed

● Simple root cause map on one page

● Temporary countermeasures within 24 hours

● Permanent fixes with owners, budgets, and dates

● Brief crews during next huddles with clear actions

● A fast script reduces repeat warehouse accident causes across shifts

13. Which rules and standards govern your program?

Let’s get clear.

● Employer obligations and operator authorizations

● Record fields and retention windows

● Report timelines after serious harm

● Contractor controls and visitor briefs at gates

● Powered truck licensing and refresh triggers

● Signage, postings, and multilingual materials

● Internal policy alignment across HR, Ops, and Safety

● Policy-driven warehouse safety tips that support compliance and prevent warehouse accidents

14. How do you measure safety without drowning in noise?

Here’s the bottom line.

● Recordable rate, lost time rate, near-miss capture rate

● Behavior checks: horn taps, belt use, load height in travel

● Environment checks: floor scores and lux readings

● Process checks: dock signal compliance and chock use

● Heatmaps by hour and zone for staffing plans

● Dashboard rhythm for daily huddles and weekly reviews

● Quarterly reviews with Finance, Procurement, and HR

● Use metrics to surface warehouse accident causes and guide targeted warehouse accident prevention tips

15. What action plan can you start this month?

What’s next?

● 7-day sprint: floors, corner marks, ladder checks, pallet rules

● 30-day builds: mirrors, lights, speed zoning, camera installs

● 90-day embeds: training cadence, audit closure, KPI boards

● Red list for capital items with owners and dates

● Communication cadence: one rule, one result, one thank-you

● Templates for checklists, huddles, and dock routines

● Publish a simple page of warehouse safety tips for every role so teams can prevent warehouse accidents daily

FAQ

Q1: What is a warehouse accident? A warehouse accident means any unplanned event on site that causes injury, illness, damage, or service loss. Near-miss events still feed learning and should be logged with time, place, people, and media for trend work rooted in warehouse accident causes.

Q2: How does incident reporting work? Team members submit a short form or app entry after any event. Supervisors add who, where, when, photos, and clips. Safety leads run root cause steps, set actions with dates, and brief crews during huddles so fixes land fast with clear warehouse accident prevention tips.

Q3: Which upgrades reduce risk right away? Add fork and rear cameras, proximity alerts, mirrors at endcaps, bright LEDs near crossings, floor tape for lanes, and guardrails at bends. Pair upgrades with speed rules and short refreshers plus posted warehouse safety tips that crews can follow.

Q4: How often should training repeat for high-risk roles? New hires get day-one onboarding plus a follow-up during month one. Higher-risk roles receive quarterly refreshers. Toolbox talks run weekly with one topic and one demo using site clips and simple warehouse accident prevention tips.

Q5: What belongs in a forklift hazard checklist? Check brakes, tires, forks, mast chains, lights, horn, seat belt, camera view, hydraulics, and power system. Add lane signs, mirror condition, floor care, and pedestrian lane status for each shift, then layer in warehouse safety tips that prevent warehouse accidents consistently.